Share your science:

A new, «Superman» way to detect hidden corrosion

SHARE YOUR SCIENCE: Even without Superman’s X-ray vision, this probe can see corrosion through 30-40 mm of steel!

The presence of corrosion, an unwanted process which turns strong steel into a brownish-reddish powder, is usually easily recognisable by its appearance. We see it on the metallic fence or on the car’s doors. And damage we see is damage we can control and fix. But is all corrosion so easily spotted? Whether it happens on the underbody of an auto-vehicle or inside a large steel tank on an oil and gas rig, the hidden corrosion is dangerous as over time, it can result in human casualties and significant economic loss. Commonly, the detection of hidden corrosion is difficult and expensive, and it comes on the radar of the traditional corrosion detection instruments when the damage is at an advanced stage, i.e. when it is (nearly) too late.

How do we find corrosion?

When a metal containing Iron corrodes it produces an easily recognisable brownish stain. Other metals such as Zinc produces a white stain and therefore it is referred to as “white” rust. Copper and Copper-alloys (e.g. bronze) forms “green” rust (known as patina). Corrosion on Aluminium is more difficult to detect with the bare eyes as its colour does not change.

Whatever the metal and whatever the colour imparted by the corrosion, a coating will hide it, allowing the corrosion to proceed undetected. This is of course not good news bridges, oil and gas platforms or for aviation.

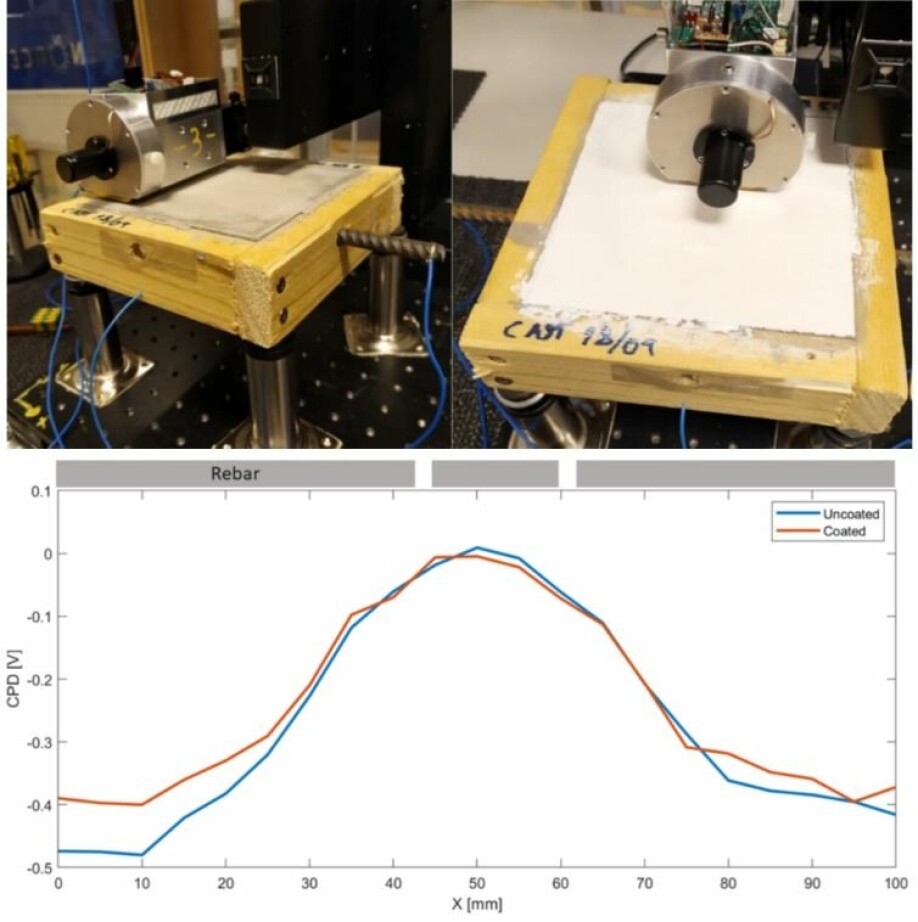

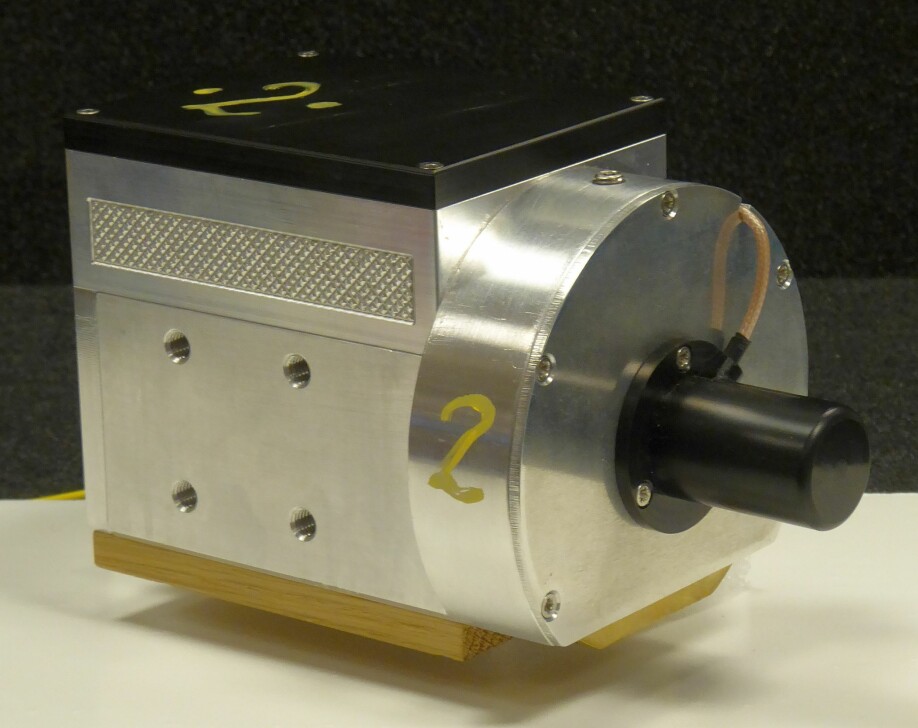

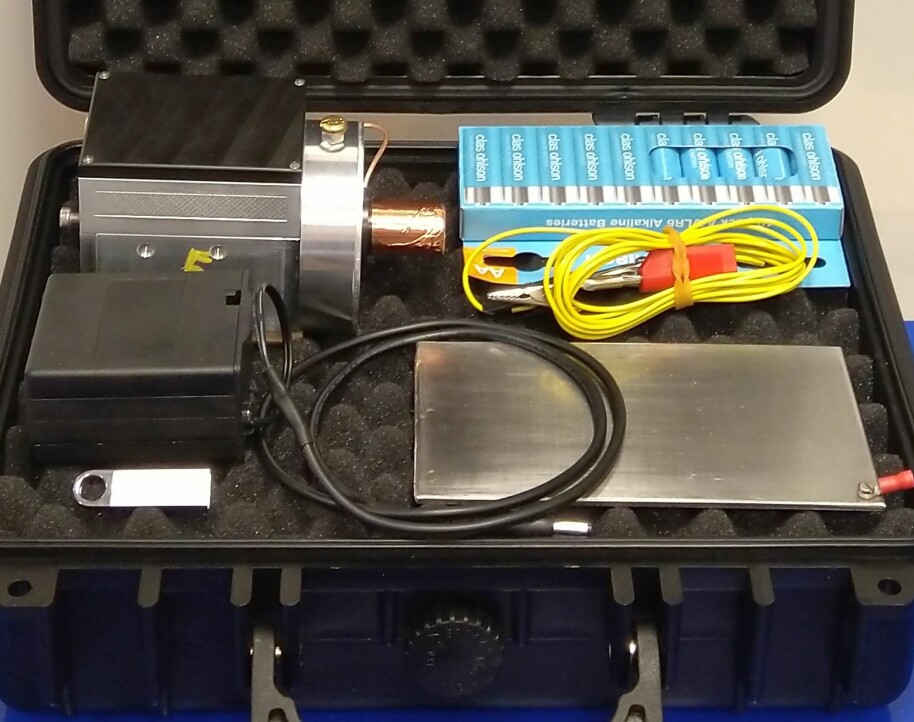

A solution to this problem comes from a team of scientists from NORCE in Bergen which developed the Field Kelvin Probe (FKP) (Fig. 1).

Detects corrosion through protective coatings

The FKP can detect corrosion also through protective coatings and since it fits into a pocket, one can use the FKP on any metal structure, whether it be automobiles, boats, oil and gas rigs or airplane.

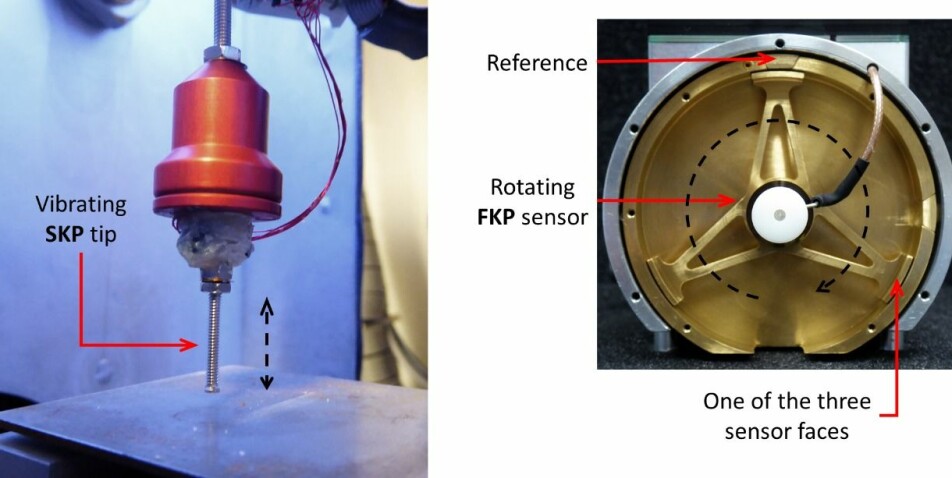

The FKP has some similarities with an older instrument knows as the SKP which is large and heavy, comparable with a present-day dishwater. As a curiosity, similar but less automated device existed about 150 years ago. However, to measure corrosion, all SKPs vibrates a sensor (up-and-down), while the FKP will rotate it (i.e. round and round) (Fig. 2).

The change in the sensor design (vibration to rotation) allowed us to make the FKP hand-held but also to impart the FKP the ability to verify the measurements against an internal reference. To make the importance of this feature clear, say someone uses a fever thermometer, but they are not quite sure the temperature is right. Maybe the thermometer is broken or maybe they has indeed a fever of 39.5°C? If the thermometer would have an internal reference which says, “the temperature you have measured is correct, whether you believe or not”, it is far more likely they would trust the temperature and call the doctor. The FKP does something similar, and it tells its user the data is fine! And this is critical when the safety of a bridge or airplane depends on properly understanding the corrosion extent.

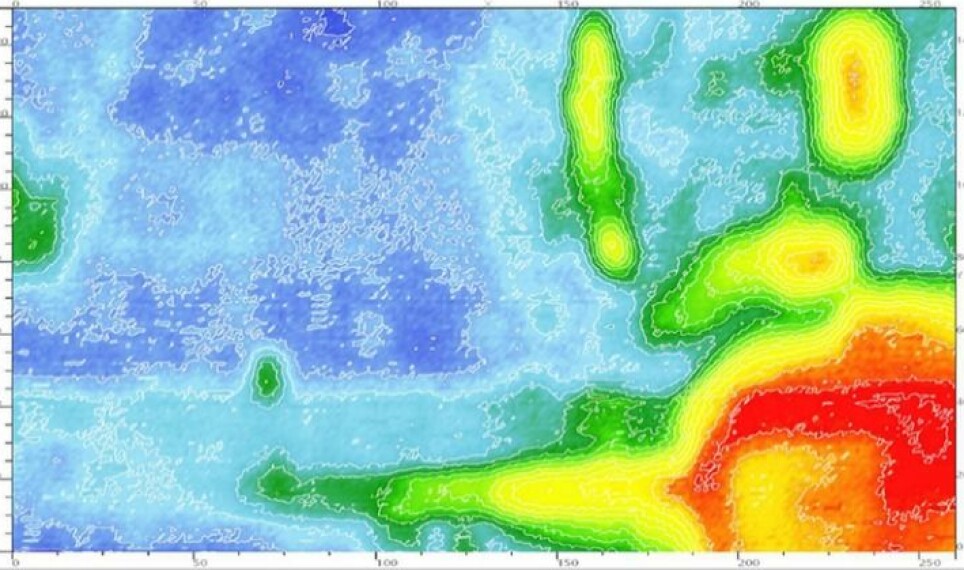

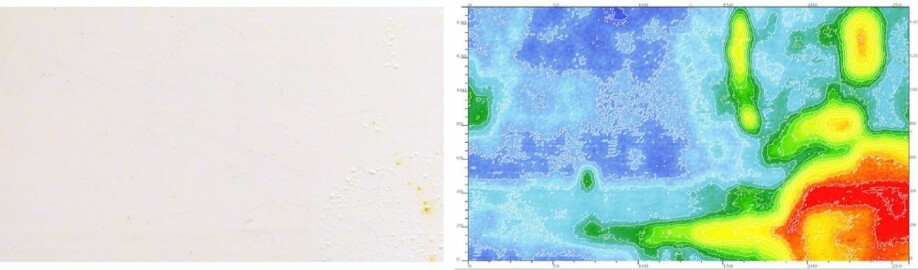

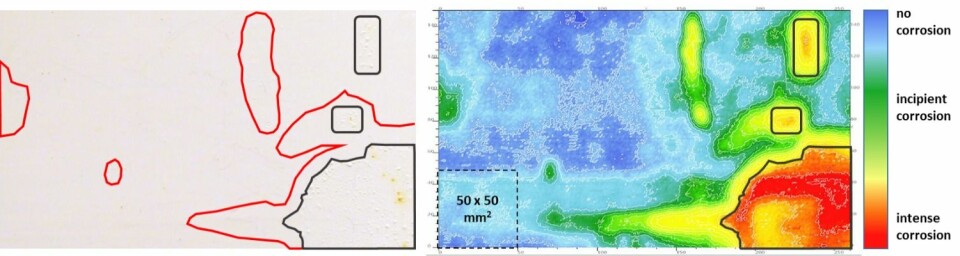

To look for corrosion, one simply holds the instrument in the hand and moves it over the area of interest. Wheels mounted on the FKP help achieve a smooth movement. The outcome of this simple measurement is a colourful and remarkably easy to understand image: a true corrosion map of the tested area (Fig. 3).

A black doted frame in the lower left corner shows the area that can typically be measured with an SKP.

Yellow and red areas indicate active corrosion! Geologist rely on “change detection maps” to monitor the impact of climate changes on the earth surface; and the colourful FKP maps do the same but to track corrosion over longer periods of time. The ease of use and clear-cut result is unique among corrosion inspection instruments.

FKP applications and uses

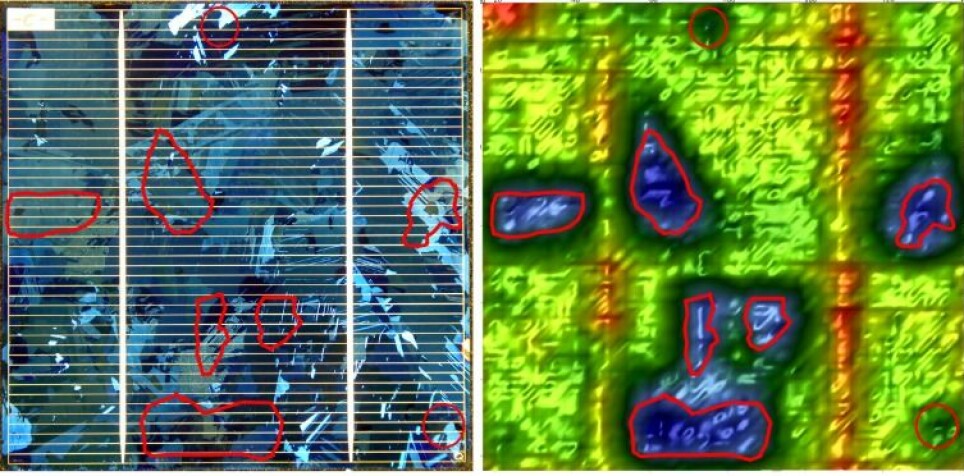

Quite obviously, the FKP has broad range of applications. For example, it could be used as an inspection device for solar panels. Besides those mentioned earlier, we believe the FKP will play a role in the solar power industry as a solar panel inspection tool. In the infrastructure, it will serve as a fast and reliable detector of corrosion on steel reinforcement (Fig. 4).

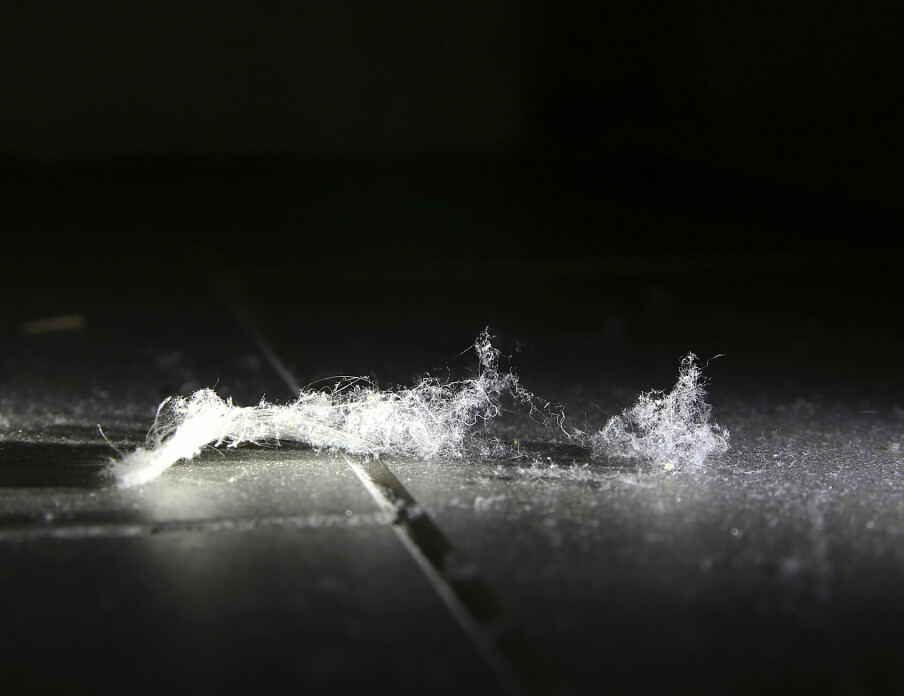

Superman has an X-ray vision and he can see through metals, right? Well, the FKP does not involve X-ray but it can “see” corrosion through 30-40 mm of steel! This is absolutely possible because when steel corrodes it releases hydrogen from the water. Some of this hydrogen travels through the steel wall (process called permeation) to the other side where it is detected by the FKP as a “hydrogen map”. The shape and size of these hydrogen map is used to point out the corrosion spot.

Rethinking old concepts

In a global market, saturated with many types of measurements instruments, it is still possible to find and fill a technology gap which will benefits large industry players but also small research groups. A rethinking of the traditional laboratory instruments and older technologies may result in more instruments leaving the comfort of a lab to serve a larger scope in the industry. The FKP, inspired by the longstanding Scanning Kelvin Probes (SKPs) is expected to become a valuable addition to existing research and engineering toolboxes.

We hope our story will stimulate the creative thinking especially among younger scientist and technology enthusiasts.

Share your science or have an opinion in the Researchers' zone

The ScienceNorway Researchers' zone consists of opinions, blogs and popular science pieces written by researchers and scientists from or based in Norway.

Want to contribute? Send us an email!