Plans underway to power up with kites

Flying generators running on wind power can revolutionise the green energy sector. A Norwegian project has made a lot of headway.

Modern kites use materials which open up possibilities beyond those conceived by kids with the toy paper-and-wood or plastic variety of a few decades ago. As seen by harnessed daredevils speeding on boards and jumping waves or traversing snow-covered polar plateaus, they pack a lot of punch.

The pulling power of kites can whip up loads of fun and thrills, but it can also be harnessed to generate electricity.

And quite a lot of electricity: A kite could cover the energy needs of two or three Norwegian homes using just ordinary wind conditions.

Have seen it confirmed

Thomas Hårklau is an entrepreneur living in Voss, a mountain town in Western Norway.

He has spent much of the last six months at an abandoned military airport in Lista, near the southern tip of the country. Along with technologists from Kongsberg, one of Norway’s key high-tech industry towns, he has made several prototypes to test kites’ energy-generating potentials.

Could they pack as much punch as hoped for?

“We have seen it confirmed. This has played out very well,” says Hårklau.

Fun as they might be, people cannot sit and fly kits hour after hour. Autopilots have to do the job. Much of the research currently pursued by the Kitemill project in Kongsberg is focused on developing a computerised control system.

In a few weeks Kitemill will launch its first operational power plant in the sky over South Norway.

Upwards of a hundred projects

The Norwegian Kitemill project is just one of many ongoing research initiatives aimed at establishing airborne wind farms. Over a hundred projects at universities and industrial centres round the world are doing the same thing.

Probably the most publicity has been generated by America’s Makani Power, which was acquired by Google in 2013.

Makani’s kite is not like the Norwegian variety. It is essentially a tethered flying wing, with propellers and generators that produce electricity up in the sky.

Kitemill and most of the other projects convert the pull of the kite to tension energy (mechanical energy) which is transformed to electricity down at a ground station.

“Makani and the Dutch project Ampyx have come as far as we have at Kitemill, maybe a bit further. Both claim to have systems that fly automatically,” says Thomas Hårklau.

“But we can have the same thing in the course of a few weeks.”

Lower winds at windmill heights

Many have faith in aerial wind power systems.

Green as they are, windmills on land have their drawbacks and many prospective wind farm projects in Norway are likely to be shelved.

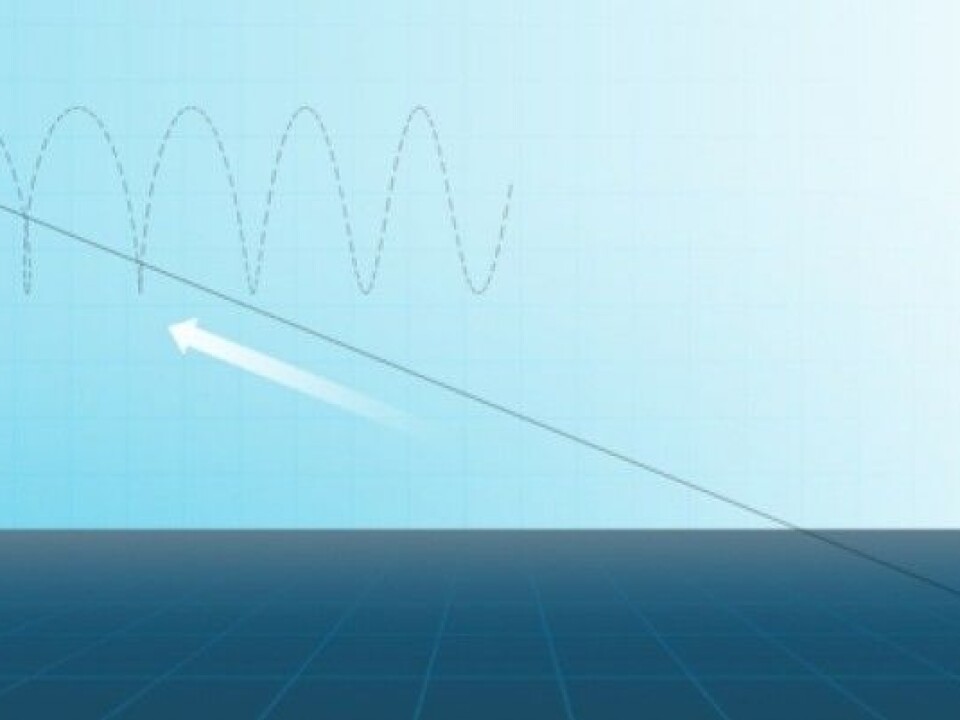

A general problem with wind is that the closer to the ground it gets, the more unstable it becomes and the less it blows.

The solution to the problem has been to build succesively higher windmills to catch stronger winds. But even with the best of construction materials we have today, they cannot get much higher.

But new opportunities arise if you attach a kite to a strong tether of polyethylene and release it. A calculation which many in the profession swear by is that the material consumption of flying wind power unit is only about one tenth of that of a comparable standing windmill.

In 2012 an average windmill in Norway could be counted on to be rotating and generating power for 2,734 hours (31 percent of the time). Kitemill claims that kites operating 1,500 metres off the ground can be in operation over 4,000 hours per year.

The goal is 1,500 metres

Small prototypes have been tested a few hundred metres above the ground. But in a few years it should be possible to harness the energy of winds 1,000 metres up.

“Kitemill’s goal is 1,500 metres into the air,” says Hårklau. Up there the wind is much stronger and more stable than down on the ground.

Kitemill reasons that by 2020 they can produce kites with an average capacity of two to three megawatts. If such a kite were operational 2,750 hours a year, its average annual output could be 0.5 to one megawatts.

An average Norwegian wind turbine currently produces two megawatts of power – as long as it is spinning.

“Kitemill is looking to scale up the technology to the same capacity of today’s large commercial windmills. But these do not need to be made that big to be energy efficient and competitive,” says Hårklau.

If in the future we can send up flying power stations to 10,000 meters, the cruising altitudes of commercial aircraft, we can tap into the energy of the jet streams. These are “rivers” of wind that blow constantly at hurricane velocities.

“However, we think 1,500 metres should be an ideal altitude for energy production,” says the Kitemill founder.

Pulling power

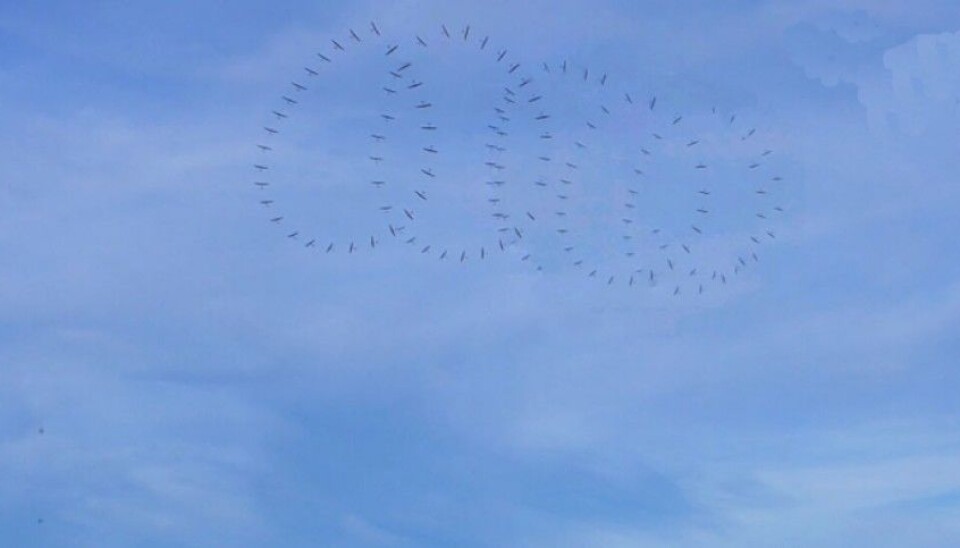

The Kitemill kite in South Norway flies in a spiral pattern as it draws a line out of winch in a small ground station.

The energy required to coil it back in, is less than two percent of the power produced when the wind pulled it out, according to tests run by Kitemill.

The technology used is called regenerative winching and is currently utilised at sea by fishing trawlers.

Birds and planes

Birds and aircraft are two of the challenges such kites would face.

“Nothing indicates that a large kite would injure birds more than a windmill does today. And the damage inflicted by rotating wind turbines on birds has proved to be much less than feared. But of course we will cooperate with experts when selecting locations for flying power stations,” says Hårklau.

The Italian KiteGen works along the same principles of the Norwegian Kitemill. Watch a YouTube video made by KiteGen showing the principle.

------------

Read the Norwegian version of this article at forskning.no

Translated by: Glenn Ostling