Researchers' Zone:

How do we make the construction industry greener? With 3D printed wax molds!

This innovative approach could reduce 20 percent of annual construction waste, while also substantially lowering manufacturing expenses.

Picture this: You're baking cookies using a cooking mold. The dough goes in and out pops the perfect cookie, shaped just like the mold.

Similarly, in the world of construction, we have something called formwork. These are giant molds, crafted from materials like wood or plastic, into which concrete is poured to help shape buildings, bridges, and other big structures.

They may not seem like a big deal at first, but they're crucial for ensuring the concrete sets into the desired form, which is essential for structural integrity.

Formworks are the pillars of the construction world, leaving a big imprint not only on the final structure but also on our wallets and our planet.

Unfortunately, old-school ways of making formwork can be quite pricey and create tons of waste, not really in line with our dream of a greener, more sustainable construction industry, right?

Well, that's exactly why we've set off on an exciting challenge to uncover smarter, circular solutions. Our goal? To change and innovate formwork creation, making it as Circular as possible!

The Problem with Traditional Formwork Production

Just like baking, construction also leaves behind its share of crumbs, but instead of cookie crumbs, it’s carbon and other emissions, not only from wasteful formwork but especially from concrete production.

This is a serious concern, considering we're trying to tread lightly on our beautiful planet.

So, we decided to explore greener options for formwork production that incentivize the use of digital tools to optimize concrete structures using less concrete.

We're looking for an approach that cuts down on waste, keeps costs low, makes the best use of concrete, and of course, marches in step with the industry's sustainability goals.

3D Printed Wax Moulds: A Game-Changing Solution

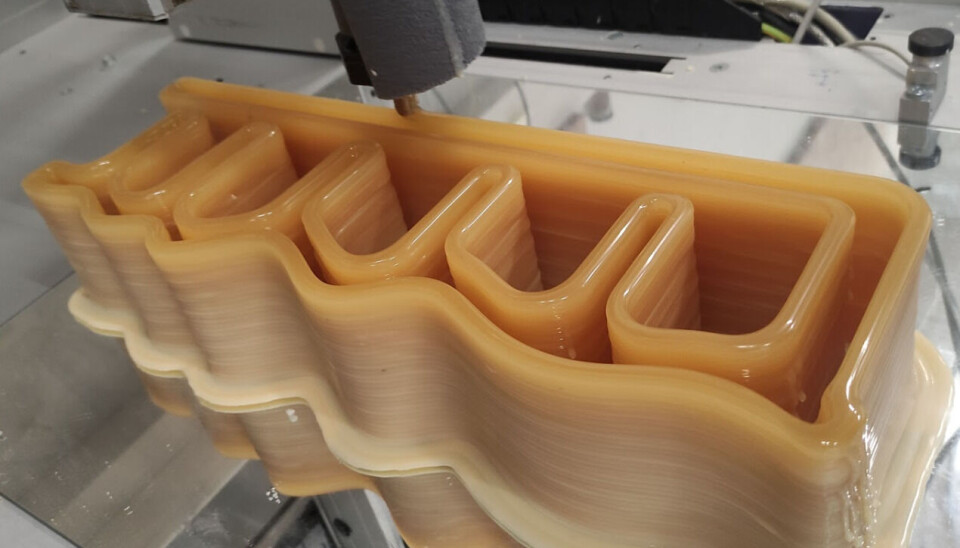

Dipping our toes into the realm of advanced technology, we're exploring a game-changing approach using a particular kind of additive manufacturing known as (MEX) Material Extrusion. Our big idea? Creating formwork using 3D-printed wax molds.

In simpler terms, imagine having a 3D printer, but instead of printing out a solid plastic object that you can't change, we print out special molds made from wax. These molds can be used to create intricate and customized designs for construction work.

One of the most remarkable features of these wax molds is their reusability. According to a study by the European Environment Agency, construction and demolition activities generate around 374 million tons of waste annually .

Another study found that nearly 20 percent of this waste comes specifically from timber formwork.

Our approach aims to tackle this issue head-on. After the mold has served its purpose, the wax can be melted down, filtered, and reused several times with minimal losses.

This not only significantly cuts down costs but also has the potential to reduce formwork waste by up to 90 percent, as indicated by a Life Cycle Assessment .

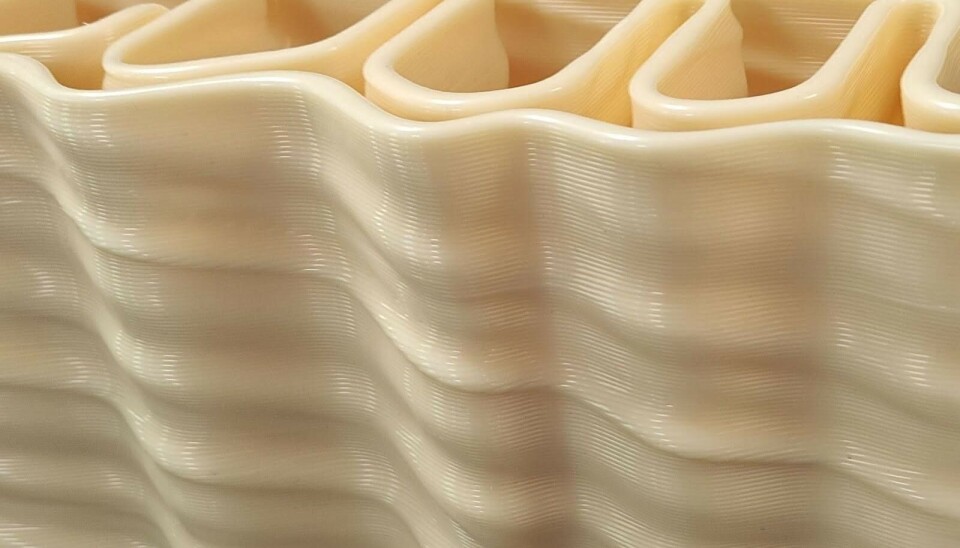

Our secret weapon is a special type of wax. It's not your everyday paraffin candle wax, but a special compound design for creating these molds.

The Technology Behind the Innovation

Right now, we're using wax for milling (that's a fancy term for carving out the shape), but we're gearing up to transition to 3D printing these molds directly in the future.

This shift to 3D printing is significant because it could potentially reduce production times compared to milling, allowing for quicker iterations and greater flexibility in design. This promising solution brings us a step closer to our goal of more sustainable construction.

Wax, the selected material, combines carnauba wax, ethylene vinyl acetate copolymer, paraffin wax, and polycyclopentadiene.

This combination is specifically designed to fabricate milled wax formwork, with properties tailored for formwork concrete casting. These unique properties make it ideal for formwork production.

The wax-based material, combined with advanced 3D printing and milling is capable of handling complex and intricate designs that can bring our vision of sustainable formwork to life.

Cost and Waste Reduction: A Sustainable Transformation

The integration of 3D-printed wax molds into formwork production brings substantial benefits.

Firstly, it drastically reduces production costs compared to traditional methods. Additionally, the elimination of excessive wood formwork reduces construction waste, contributing to a greener and more sustainable construction industry.

Studies have shown that the manufacturing costs of free-form wax formwork molds, including the recycling process of the wax, are lower than those of conventional EPS040 (a type of the commonly known flamingo or styrofoam) which is a type of ‘disposable formwork’.

Additional incentivizing the use of optimization techniques for concrete structures not only could help minimize concrete consumption, but also optimize the performance of concrete structures.

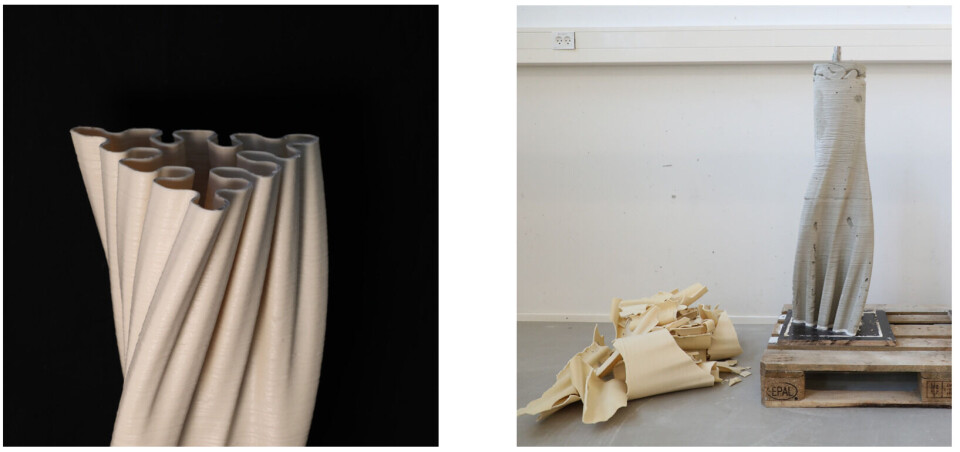

In the left image below, a finished 3D-printed wax formwork showcases the precision and intricacy of modern construction technology. On the right, a concrete column stands tall, complete with a reinforcement tube.

Next to it, the wax mold that was used to shape the column lies broken, ready to be collected and recycled. The column itself rests on what was once the scaffold of the formwork, highlighting the full lifecycle of this sustainable construction method.

Embracing a Sustainable Future

While our study is currently in the writing process and is intended for publication in a scientific journal, it has already shown promising results.

We are also conducting rheological measurements (studies on how the material flows(?)) to further explore and optimize our methods. We anticipate publishing these comprehensive findings by the end of 2023.

Scaling up the use of 3D-printed wax molds in the construction industry requires further research and development.

This includes refining the printing process, exploring new printing techniques, optimizing the material.

We also need to integrate computational optimization methods to further enhance the performance and efficiency of final concrete structures using the advantages that the wax formwork could offer. This is illustrated in the pictures below.

A Greener Path Forward

The combination of 3D printing technology and wax-based materials unlocks a realm of possibilities in formwork production.

By embracing this innovative approach, we have the power to achieve remarkable cost reductions.

3D-printed wax molds provide a game-changing solution for the construction industry, effectively reducing waste and slashing costs.

By adopting this groundbreaking approach, we can make significant strides toward a greener and more sustainable construction sector.

Creating a greener and more sustainable construction industry requires collaboration between researchers, industry professionals, and policymakers.

By working together, we can drive the adoption of additive wax formwork and other sustainable practices in construction. Together, we can shape a future that is both environmentally conscious and economically viable.

Together, let's embrace environmentally conscious practices and shape a future that benefits both society and the planet.

Project supervised by: Prof. Roberto Naboni, Create at SDU and Asbjørn Søndergaard, CTO Odico A/S