Magnetic screw helps capture energy from waves

Wave energy is known for its great potential, but so far no-one has found the right way to exploit the movements of waves. Three newly qualified engineers have come up with a great suggestion

For many years, wave energy has been wind energy’s ugly-duckling cousin.

While the Danish-based Vestas has had international success in designing and building wind turbines that effectively turn the energy in wind into electricity we can use in our homes, businesses and growing fleet of electric cars, the potential of wave energy remains untapped.

“There are not yet any commercial installations that are really profitable,” says Rasmus Holm, who has just completed his master’s degree in engineering at Aalborg University.

“The existing installations are not good enough at capturing the energy in waves. But the advantage of wave energy is that the sea has waves even when there is no wind. This makes wave energy worth looking at, even though it’s difficult.”

Another new engineer, Nick Ilsø Berg, adds: “I read that if we could make efficient wave energy installations along Denmark’s west coast, where the North Sea is, we could cover 15 percent of Denmark’s energy consumption. And the west coast is sheltered by Britain.”

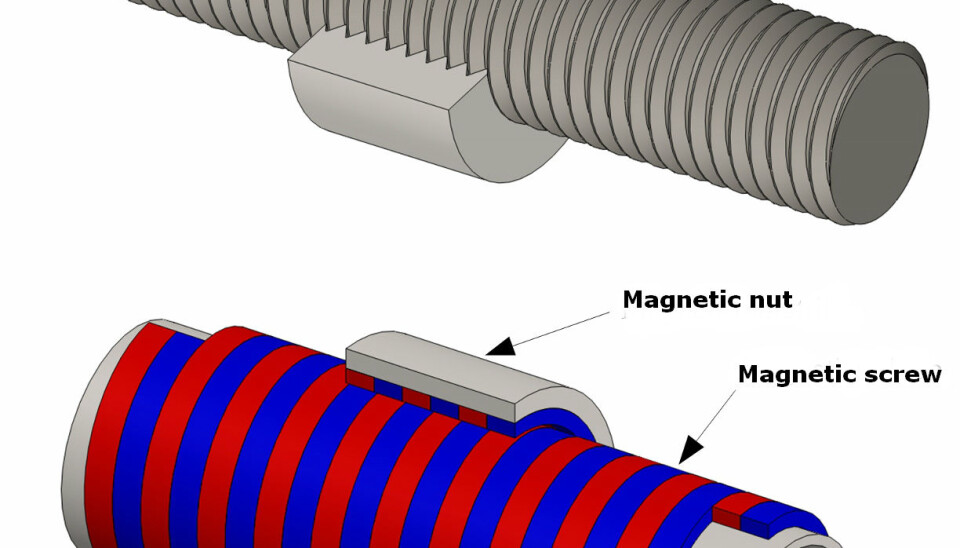

Together with a third new engineer, Morten Walkusch, Holm and Berg built a magnetic screw as part of their master’s degree project. They believe that, over time, a magnetic screw will help wave energy reach its potential as a source of energy.

Capturing wave energy

That something as simple as a screw can make a difference in solving a complicated matter like exploiting the energy of waves is due to the way a screw converts the energy in waves’ regular, linear, up-and-down movements to a fast rotary movement.

The energy in this movement is then transmitted to a generator, where it can be tapped and used.

Existing wave energy installations are primarily based on hydraulics. In these hydraulic systems, the vertical movements of the waves drive a piston back and forth in a hydraulic cylinder.

This causes oil under high pressure to flow through tubes to a hydraulic motor, which converts the oil flow into rotary movements of an axle. A generator connected to the axle then turns these rotations into electricity.

“Our magnetic screw replaces both the hydraulic cylinder and the hydraulic motor, as it converts the linear energy into rotations directly,” says Walkusch.

Magnetism is a very effective method

“The conversion efficiency of hydraulic systems – the ratio of the energy coming in to the energy going out – is 60-70 percent at best,” says Walkusch. “This means that 30-40 percent of the energy is lost. We have had a conversion efficiency of about 85 percent in the initial tests with our magnetic screw prototype, but the potential is closer to 90-95 percent.”

The 30-40 percent energy loss arises primarily because the hydraulic system is operating far outside its ideal working range for much of the time that it’s used to capture wave energy.

“It’s a characteristic of wave energy that there are extremely large differences in how much energy can be captured from large and small waves,” says Walkusch. “To capture the energy in large waves, which have the most energy, the hydraulic system must be relatively large and powerful.”

But a large and powerful hydraulic system is not very suitable for capturing energy from smaller waves, which the system must do for most of the time.

The hydraulic system thus often operates under conditions that are not optimal. And that means energy is wasted, he adds.

A screw like no other

The three new engineers from Aalborg University are the first to have developed a prototype magnetic screw aimed at capturing wave energy.

A similar construction was patented in 1942 and was used for monitoring the sea level, and the magnets drove the meter disc.

Since then it has become possible to make much more powerful magnets and this has opened the door for building the magnetic screw.

“Our magnetic screw is a completely new application, and the prototype in the laboratory here is the only one of its type in the whole world,” says Walkusch. “The idea has been described theoretically in scientific papers, but as far as we know no-one else has made a prototype.”

No other finished prototypes

Peter Omand Rasmussen, a associate professor at the university’s Institute of Energy Technology and a specialist in electrical machines, was the supervisor for the three newly qualified engineers’ master’s project. He confirms Walkusch’s claims:

“We have seen a patent application from the 1990s in which American researchers presented a miniature version of a magnetic screw for use in heart pumps – but we don’t know whether it was ever made,” says Rasmussen.

“Some researchers at Sheffield University in England published an article on a theoretical magnetic screw last year, and there are undoubtedly many people trying to construct them. But as far as we know no other finished prototypes exist apart from the one we’ve built here at Aalborg University.”

Promising, but not yet commercial

Although the idea at the prototype stage seems very promising, a long path has to be trodden before we see wave energy installations based on magnetic screws along Denmark’s coasts.

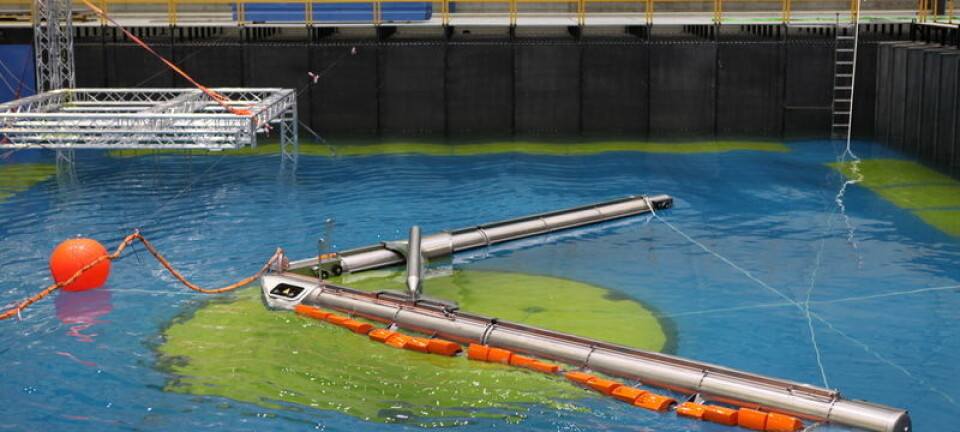

“Part of the project is financed by a company called Wavestar,” says Holm. “Wavestar uses hydraulics for capturing the energy of waves in their current installations, but they believe that our project has some interesting perspectives for the future. For the coming years, however, the technology will still be hydraulics.”

This is because much more money and research are needed to develop the magnetic screw into a product that can be used in real wave energy installations.

-------------------------------

Read this article in Danish at videnskab.dk

Translated by: Michael de Laine