Abstract maths can boost machinery

Abstract mathematical models can help businesses optimise their manufacturing equipment, new study suggests.

The equipment that businesses use in their production isn’t always optimally designed in terms of effect and profit.

The design of this machinery is often more or less based on random results from decades of development and adaption of old ideas.

Mathematical models, it now appears, can help solve this problem.

“My research illustrates how mathematical modelling can contribute to the improvement of exisiting machinery in industrial production. It’s a question of approaching science in a new way,” says engineer Joakim Juhl, who recently defended his PhD thesis at the University of Aalborg, Denmark.

Reduced energy consumption

Scientists shouldn’t always seek to develop general and universal theories, even though that’s usually what’s regarded the ‘purest’ science. If you want your research to have any use in society, it’s important that you also base your research on real-life problems.

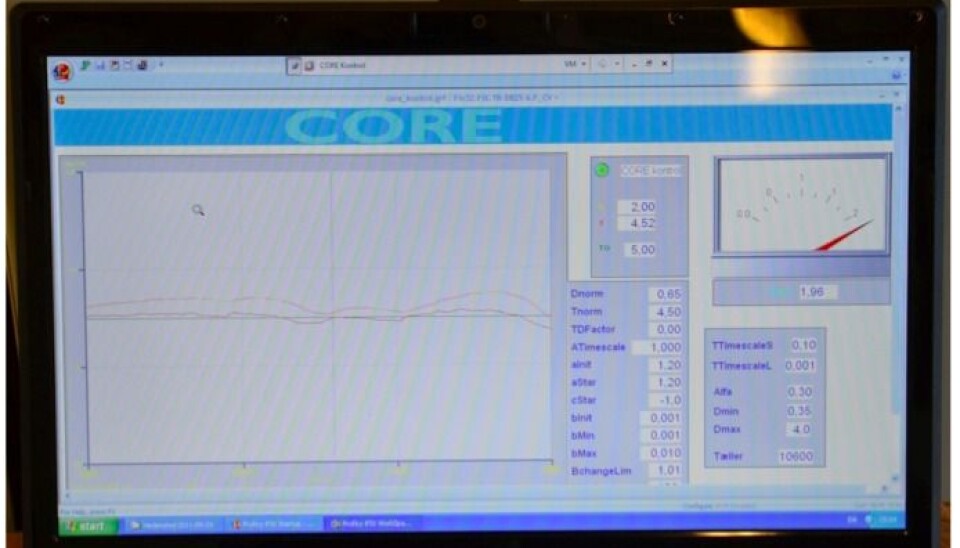

The thesis, ’Models in Action – realising abstractions’, describes how mathematics was used to optimise the ‘intelligence’ of the industrial machinery at the Danish company Daka, which produces bone meal for animal feed from waste products from pig production.

This optimisation resulted in a reduction in the company’s energy consumption.

However, the thesis represents research that’s a bit different from the usual procedure in which vast data is collected, eventually resulting in a more or less clear-cut conclusion.

A different approach

Instead of collecting data, Juhl carried out a case study in which a team of experts described their attempts at optimising Daka’s machinery using mathematical modelling.

The team, consisting of mathematicians, physicists and engineers were first asked to identify the physical principles ‘behind’ the equipment so that they could simulate its functions on a computer.

They were then asked to develop concrete optimisation solutions and then implement them into the machinery.

From theory to reality

The scientists used some basic laws of nature as the starting point, since industrial machinery relies just as much on e.g. gravity as everything else in the world.

One problem with these so-callled laws of nature, however, is that they only describe idealised phenomena. In other words, these laws only apply under specific circumstances, for instance in laboratory tests where all confounding factors can be strictly controlled. But with real-world production machinery, things are a bit more complicated.

Model can fine-tune machinery

To overcome this hurdle, the experts incorporated several different physical theories into their mathematical models.

This enabled them to get as close as theoretically possible to how the machinery works in practice.

One of the main challenges at Daka is that the composition and the amount of pig remains are constantly changing.

The team managed to develop new ’regulations’ of the control signal in the dryer – i.e. new ways of responding to the raw material that’s fed into it. This made it possible for the machine to ‘intelligently’ regulate how the amount of pig remains it receives any given day.

The more contrete, the more useful

“Scientists shouldn’t always seek to develop general and universal theories, even though that’s usually what’s regarded the ‘purest’ science,” says Juhl. “If you want your research to have any use in society, it’s important that you also base your research on real-life problems.”

------------------------

Read the Danish version of this article at videnskab.dk