Human blood can help rescue world’s climate

Today CO2 is removed from industry by using molecules called amines, which react with CO2. DTU has developed a new method using molecules from the human blood to remove CO2. The new technology could help prevent climate change.

Governments around the world need to act quickly in order to avoid further changes to our current climate. The Danish government recently took an important step to reduce the emissions by 70 percent before 2030. This requires ambitious innovation.

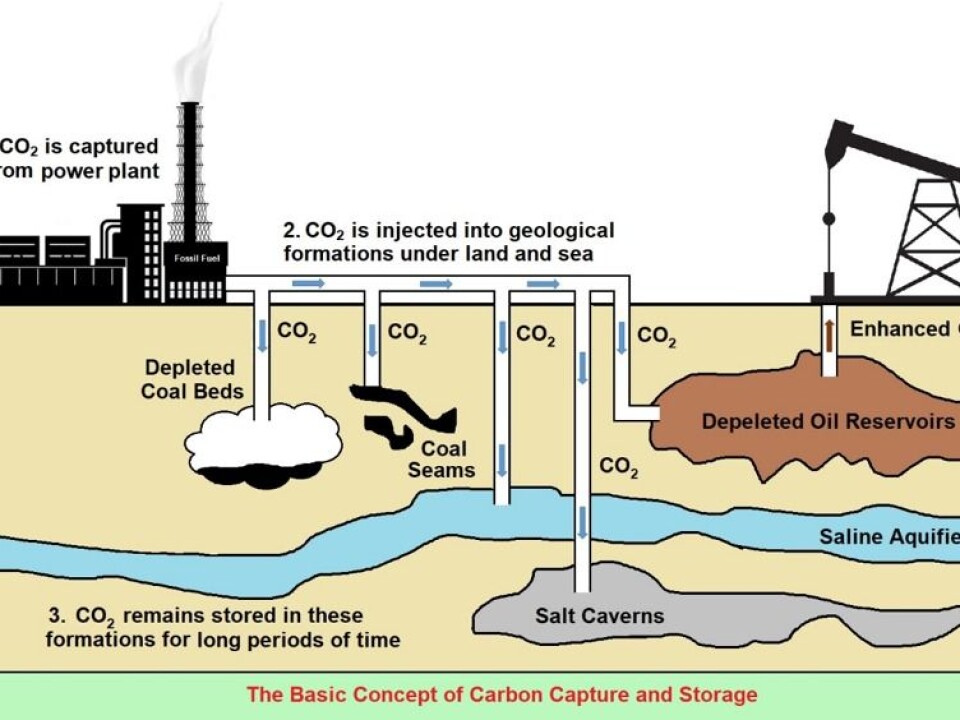

Until our reliance upon fossil fuels dwindles, it would be cheaper and more logical to prevent CO2 from reaching the atmosphere by cleaning the exhaust gases from industry rather than trying to remove it from the atmosphere.

The idea is similar to wastewater treatment plants cleaning water at the source, instead of polluting and cleaning the oceans years down the line.

Hence, we need to apply CO2 capture and storage (CCS) on an industrially large scale in order to secure the climate and avoid further global warming.

Bio-based materials are the way forward

Although an organisation like Greenpeace believes that carbon capture and storage is a short term solution, the long-term commitment is heavily dependent upon the method used.

The IPCC’s report on global warming from 2018 states that even if we successfully cut down on our use of fossil fuels, we still need to start removing CO2 from the atmosphere.

The more sustainable the technology is, the better global warming is abated. Future CCS systems must utilize bio-based materials that are close to the natural mechanisms, like, human respiration or plant photosynthesis. These natural processes are known to regulate carbon dioxide levels with moderate use of energy and effort.

The current CCS technology uses organic molecules called amines. It is the most widely used method for capturing CO2 from combustion waste products.

The process uses an arrangement of an absorber and a stripper. The absorber separates CO2 from the gas mixture at low temperature. The CO2 is then collected in the stripper using high temperature. However, as good as they are, amines are synthetic organic chemicals, i.e. they do not have a biological origin like in nature.

Replacing them with materials from a biological origin can set the right balance. The production and handling of biological materials is easy. They can be produced in abundance and do not require high temperature and pressure for production.

How the human blood can help

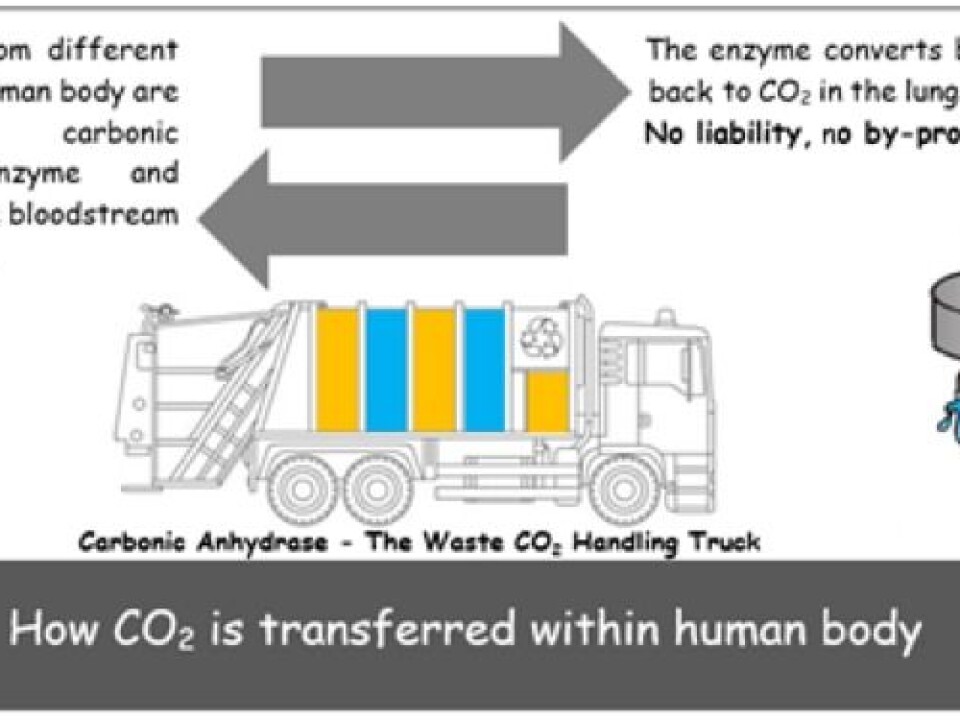

The human blood is composed of many biological chemicals and compounds. It transports nutrients like, oxygen, proteins, sugars and fats to our body cells. Similarly, many waste products are carried the other way by the blood, which include carbon dioxide, a by-product of our metabolism. Moreover, various co-helping agents like enzymes and electrolytes maintain a fine balance in blood’s composition and keep our body healthy.

Enzymes are biological catalysts that enormously increase the rate of the chemical reaction. Many enzymes are present in our blood and carbonic anhydrase is one of them. This enzyme helps to capture CO2 from our various body parts and release it in our lungs in a pure form, where it is subsequently exhaled.

The enzyme has some promising characteristics. It can carry on doing this process again and again and can easily work at normal conditions (i.e. like in the environment, we inhabit). When employed in existing carbon capture plants, the enzyme can capture CO2 forever.

The process imitates the human lungs where carbon dioxide is separated in a pure form, from various components within the bloodstream.

Recently, we have studied the carbonic anhydrase enzyme extensively (provided by Novozymes Inc.), for industrial carbon capture applications at DTU.

The results are highly promising and indicate that a combination of enzyme with a carrier biological material can efficiently separate CO2 from the mixture of gases.

The results ascertain the development of a new process that can chemically absorb CO2 in the biological material. The bio-based molecules carry the dissolved CO2 to the stripper. Here the dissolved CO2 is converted back to gaseous CO2 at low pressure and the same temperature as of the absorber. The operation potentially promises energy savings and environmental sustainability.

Our best estimation is that the process has the potential to disrupt the field of CO2 capture. Using bio-based molecules, we are almost creating artificial lungs for the world.We are now focusing on developing a bio based carbon capture and storage (Bio-CCS) process for the carbon capture plants. The new technology concept shall be available for first commercial use by the next decade.

It will work, but is it enough?

The technology is most suited for direct use in high CO2 emission industries and shall make them CO2 neutral. Most of the heavy carbon dioxide emissions come from the stationary sources. This include electricity stations, cement plants, pharmaceutical firms, paper factories, biogas producers and local heating systems.

It is quite alluring to have a process that can act similar to actual human lungs, pulling out CO2 using natural materials. If climate change is to be limited, we need a variety of approaches. But these approaches must be close to nature’s own processes in order to be technologically doable and societally acceptable.

At least we are certain that this technique works. It does not require large capital inputs. However, we cannot rely on a single university or company to fight and win the ‘war’ against global warming.

Concerted efforts are required to reduce the greenhouse gas emissions. This means introducing Bio-CCS in individual industries will not be enough. Global Bio-CCS schemes must be established to achieve a carbon negative emission standard by year 2050, meeting the goals of the Paris agreement.

The proposed technology needs an industrial base to mass-produce the required chemicals. It requires extra time and resources. However, we believe that the economy of scale can help reduce a large portion of incurred costs.

From our engineering perspective, the new technology is ‘one small step for CCS, one giant leap for environment’.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No 754462.

Read this article in Danish at our sistersite Forskerzonen.