That dream screen is just around the corner

A Danish chemist expects the first new super-thin graphene screens to be in stores quite soon. But we may have to wait a few years for computers that use this miracle material.

Chemists and physicists are generous with superlatives when describing their new darling, graphene.

The thinnest material in the world, graphene is 200 times stronger than steel and is an unrivalled conductor of heat and electricity. These are but a few of graphene’s extreme qualities that prompt scientists to label the one-atom-thick planar sheets of carbon 'a miracle material'.

In August, a number of Europe's leading graphene researchers gathered for the Carbonhagen 2011 conference to discuss their latest graphene-related laboratory findings.

Graphene flat screens a year from now?

Soon the super-thin material will part company with the white lab coats and flasks to join you in front of your sofa in the shape of even thinner and faster-reacting flatscreens, predicts one of the conference's organisers, Bo Wegge Laursen, who is also involved in graphene research at the Institute of Chemistry at the University of Copenhagen.

Although only seven years have passed since scientists became able to produce and examine graphene in free form, research has already come so far that the first screens made from graphene could be ready to go into mass production.

"It may not be very long until we will be using transparent electrodes made of graphene in commercial products. Graphene might be used in flat screens a year from now," says Laursen.

Huge sheet of graphene from South Korea

Researchers have long been struggling to produce graphene in sufficiently large pieces, but last year good news emerged from South Korea.

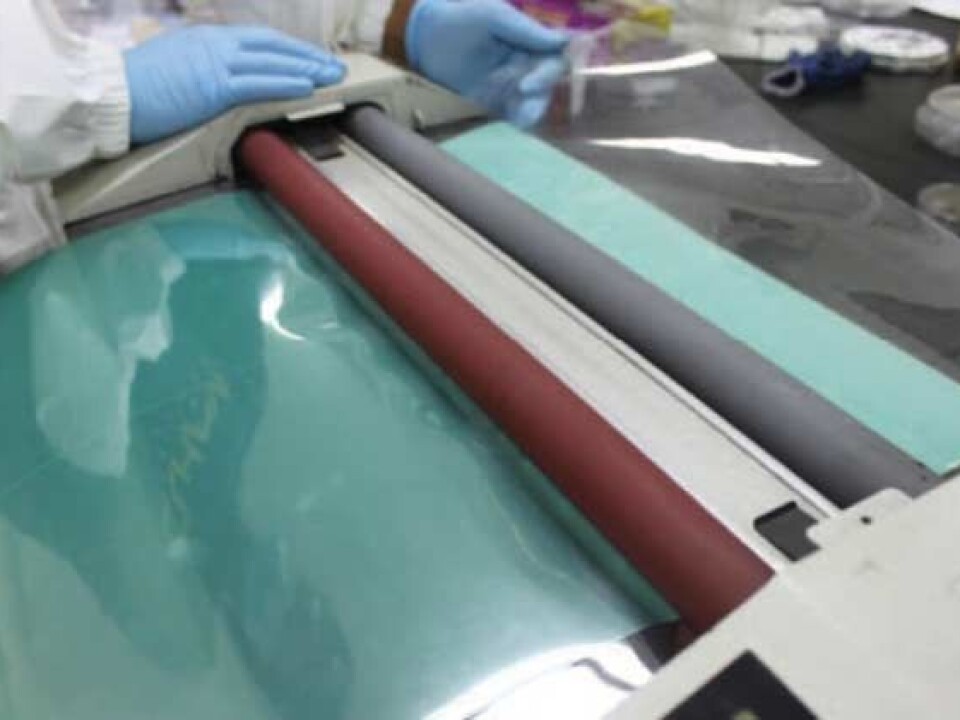

In collaboration with Samsung, researchers from Sungkyunkwan University have succeeded in constructing a 30-inch sheet of graphene which could be used for touch-sensitive screens of the kind we know from smartphones.

The South Koreans used chemical vapour deposition to grow graphene on a copper roller. They then used a piece of sticky plastic to separate a layer of graphene from the copper. To strengthen the graphene film they repeated the process until they had four layers of graphene on top of each other.

Foldable flat screens and unbreakable mobiles

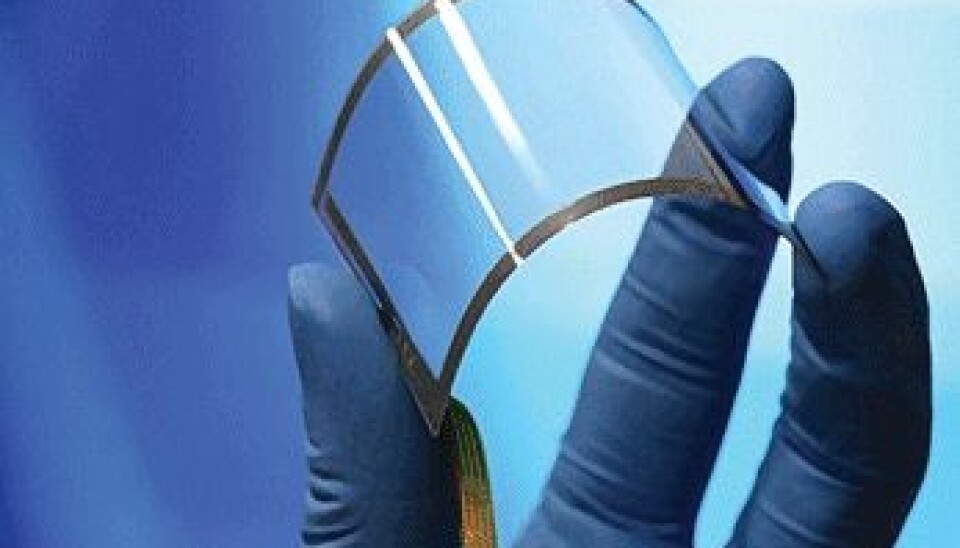

Although the South Koreans' method did not result in a perfect single layer of graphene, subsequent treatment of the graphene sandwich with nitric acid made their sheet good enough for use as a transparent electrode.

"It is possible to make do with a 'poor man's' version of graphene, in which flakes of graphene are laid out together to form a network, because domestic flat screens do not depend on super-high conductivity," Laursen explains.

He sees the Koreans' technique as promising and believes that by using this method, graphene can eventually replace the indium tin oxide used today as transparent electrodes in flat screens, touch screens, LED lamps and solar panels.

This would be highly practical because indium tin oxide is a rare, expensive and fragile material. Graphene, on the other hand, consists of a single layer of carbon, one of the most common elements. Graphene is also flexible, which paves the way for foldable flat screens and mobile cell phones that can be dropped without their screens breaking.

Graphene computer chips still in the distance

Other uses of graphene, on the other hand, will be a long time coming, Laursen believes.

"Obviously, graphene will not replace silicon in computer chips any time soon - if indeed it ever does. One reason for this is that many of graphene’s special qualities derive from the fact that the material is formed in a single perfect layer without cracks and folds."

This means that the South Koreans' method is not good enough for making computer chips. The way to make the purest graphene is by using the original method from when it was first made in free form in 2004.

Creating perfect graphene is laborious

Back then, a group of researchers from the University of Manchester in England simply took a piece of graphite and tore off small flakes of it with a piece of tape – rather like when you write with a pencil which leaves a thin layer of graphite on the paper.

When a suitable piece of the tape has caught a little graphite, the piece is pressed onto a surface and with a bit of luck, a single layer of graphene will be left behind. Unfortunately, this method is far too low-output for use in mass production.

"You can't base an industry on having a billion people sitting there with pencils and microscopes looking for single flakes," says Laursen.

Progress depends on companies

For grapheme to be used in the lightning fast computers of the future, researchers will have to invent some new methods of producing large quantities of graphene of a sufficiently high quality.

That said, researchers still have to work out how to switch off graphene’s conductivity and how to make electronic circuits with graphene.

This is not likely to happen until current computer chips made out of silicon can no longer be developed any further, he believes.

"If silicon technology really does come up against a wall and cannot be further improved, the rewards and the effort involved in finding alternatives will grow. But as long as you can just keep going with silicon, why bother making serious efforts to find something new?

"Of course there will be researchers who will work on alternatives. But the turning point will ultimately arrive when the industry realises that there is a reason to change," concludes Bo Wegge Laursen.

Read the article in Danish at videnskab.dk