Vikings versus Iron Age: Who made the best swords?

How important was steel for the Vikings? Would someone from the seventh century stand a chance against a tenth century Viking warrior?

One day in the seventh century, a well to do man was buried according to custom.

The family carried his dead body up to the gravesite, they dug a hole in the soil and laid him there on his back with his arms down by his side, dressed in the clothes that he wore when he took his last breath.

Inside the grave were his dog, his knife, and his sword. The dog was resting by his feet, the knife in his belt, and the long single edged sword along his left hand side.

The blade of the sword was almost one metre long and half a centimeter thick. It was both strong and heavy.

Such a sword was clearly the weapon of choice at the end of the Iron Age, when a man’s status was indicated by the grave goods he was buried with.

Read More: The Viking Age should be called the Steel Age

We now know how swords were forged

One hundred years later the double edged sword that was last used in the Nordic Roman Iron Age, started to make an appearance again at the beginning of the Viking Age.

And today we know how these swords, both the single edged Iron Age sword and double edged Viking sword, were forged.

But were they both as effective as they were impressive?

Of course it was not only the shape of the swords that marked them out as different. There was also a difference in the quality of iron forged in their making.

Read More: English mass grave contains remains of Viking Great Army

With enough carbon, iron becomes steel

In the late Iron Age and Viking Age, iron was not just iron but a material of many qualities.

Chemically it was rather pure and contained only a few contaminants (less than one percent), primarily phosphor and carbon.

But the sword smiths knew how to exploit these nuances: The clean iron was soft and welded at a low temperature, the phosphoric iron could be etched to a beautiful silver-like colour and the carbon iron (steel) could be hardened.

Danish Viking blacksmiths worked with iron that contained around 0.8 per cent carbon, and when it hardened it had the strength of modern day steel.

The difference between iron and steel is the amount of carbon: Iron that contains more than 0.35 per cent carbon becomes steel.

Read More: Denmark’s first Viking king printed in 3D

A thousand years’ experience in a sword

Unlike modern iron, all iron produced in the past contained slag—a waste product created during the production process.

Old iron extraction processes were not particularly effective, and never really reached the temperature at which iron and slag are entirely separated.

The tiny pieces of slag inside the iron were trapped during the reduction process and then when the bloom iron was beaten into iron pieces and forged into a sword.

Working with this material required extensive experience, as the small pieces of slag gradually worked their way up to the surface with each strike of the blacksmith’s hammer.

If this happened during a critical stage in the manufacturing process it could have a devastating effect on the sword quality, while also disfiguring the swords overall appearance.

But seventh century blacksmiths were very talented, drawing on more than a thousand years’ experience of working with slag-rich iron.

Read More: Rusty rivets reveal origin of Icelandic viking ships

A sneak peek inside a sword

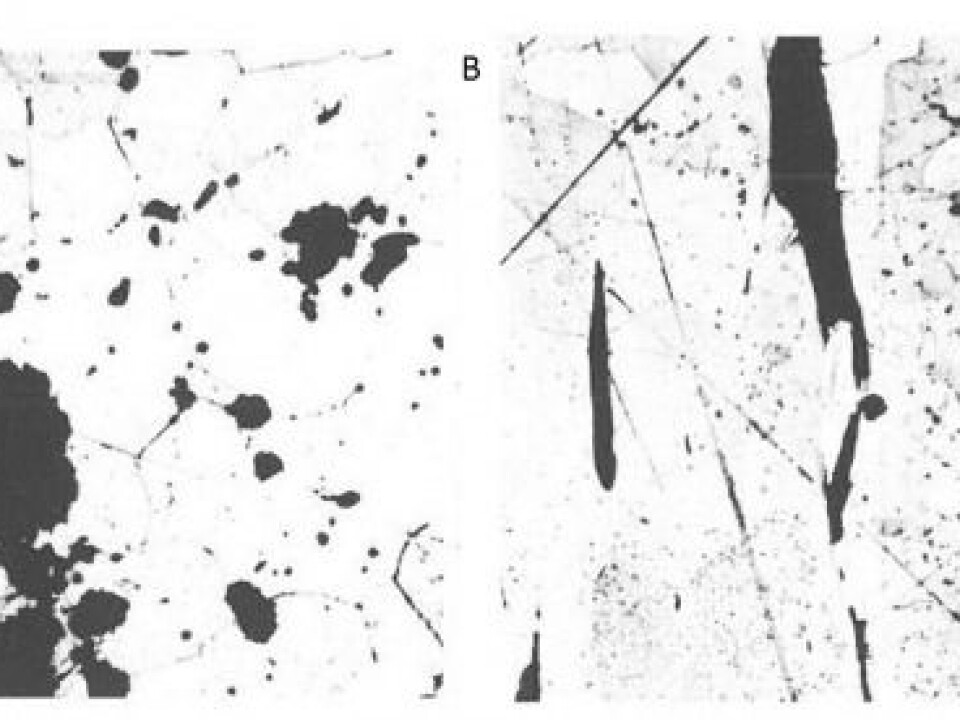

If you slice a sword blade in half and study it under a microscope, you can clearly see how many pieces of iron were used to produce it. You can also see how the pieces were welded together and the quality of iron used in each piece.

You can also see how many small pieces of slags are contained inside the iron, and their shape.

Experiments at The Land of Legends, at the Centre for Historical-Archaeological Research and Communication in Denmark, have shown how the amount of slag and its shape differs in different types of iron. The slag in iron that has just been removed from the furnace is rounder and there’s more of it, while iron that has been forged for longer contains less slag and it is flatter.

Under the microscope, you can see the amount of phosphor and carbon, and get an idea of how long the iron was forged by the individual pieces of iron. It also tells us how talented the smith who crafted the sword was.

Read More: Archaeologists finally know how old Denmark’s fifth Viking fortress is

A good craftsman, but less effective material

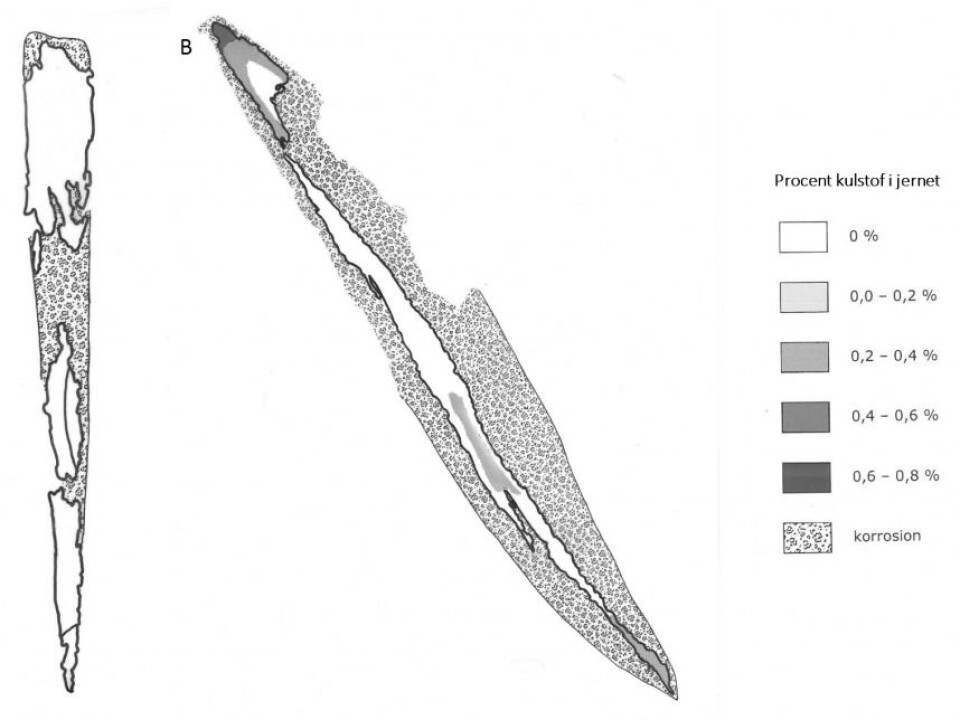

Cross-sections of seventh century swords reveal that they were forged from a number of pieces of pure iron, with numerous oval slag incursions and almost no carbon.

But the iron pieces are often homogenous and neatly welded together, indicating good craftsmanship despite using rather inappropriate iron.

Iron with such little carbon is rarely used to produce steel, which would have made a harder sword.

But perhaps the blacksmith was more concerned with producing a blade of a certain size and shape than to optimise it for use in battle, which after all, probably played a different role in the late Iron Age culture than for the Vikings.

Read More: Did Vikings really fight behind a shield wall?

Like comparing a propeller plane to an F16 fighter jet

The techniques used to produce the Viking swords is completely different.

The quality of the iron is also completely different, even though they used locally produced iron that contained lots of oval slag. But these swords were made of hardened steel.

Viking blacksmiths used a new technique, combining pure iron for the middle of the blade and steel along the edges.

The steel often contained just a few, flat pieces of slag, indicating that it had been worked over a longer time than the pure iron. These craftsmen cared about the sword’s appearance, but also its effectiveness in battle.

The difference is in no way insignificant.

Comparing a sword made of pure iron with one edged in steel is like comparing a propeller airplane with an F16 fighter jet.

An Iron Age warrior could still cut and stab with his sword, but the Viking’s steel-edged sword was much more effective.

Read More: What made the Vikings so superior in warfare?

From the Iron Age to the Steel Age

It’s worth mentioning that this technological shift between the early Iron Age and Viking Age did not only apply to swords that indicated the high status of its owner.

Knives found in ordinary Viking graves were similarly forged with well worked steel between two pieces of iron, unlike the earlier examples of Iron Age knives.

This provides an optimal construction that combines the strength of steel with the flexibility of iron in one indestructible blade. Its application to crafting weapons and tools must have massively improved their effectiveness.

---------------

Read this article in Danish at ForskerZonen, part of Videnskab.dk

Translated by: Catherine Jex