Pine resin and alfalfa seeds can help ‘sprout’ new lithium-ion batteries

Researchers at Sweden’s Uppsala University have developed a technique to extract the lithium from spent batteries and combine this with renewable biological material, to create a battery with a similar energy capacity to that of ordinary lithium-ion (Li-ion) batteries.

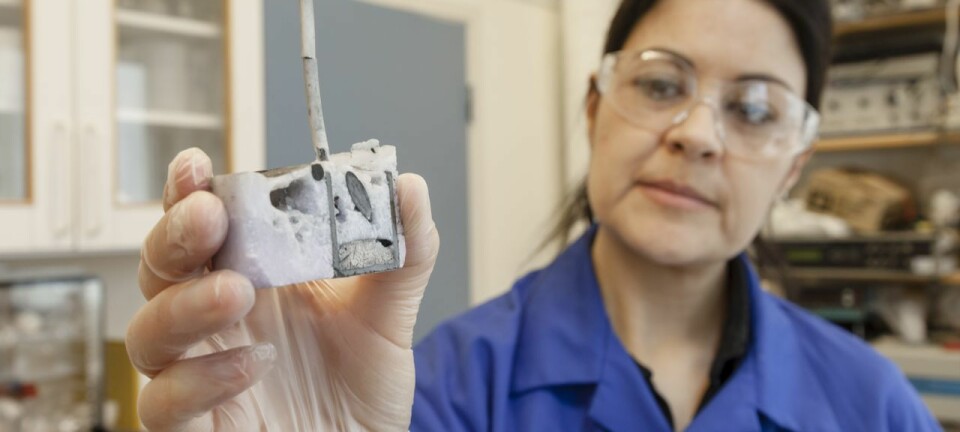

Scientists at Uppsala University’s Ångstöm Laboratory think that they may have found a greener way to make new batteries from old ones – combine the salvaged remnants of a depleted Li-ion battery with completely organic materials derived from alfalfa seeds and pine resin to create a recycled biomaterial Li-ion hybrid battery.

Using materials from alfalfa – a plant in the pea family – and resin from pine trees they have come up with a good recycling strategy for batteries that are used in a host of household products, laptops and electric vehicles like the Tesla and the Nissan Leaf. The odd combination of organic material can help extract the lithium from a worn-out battery to make a recycled, biomaterial Li-ion hybrid battery.

Fascinating

“This sounds fabulous. But I know this research group well and they present high-quality research. The battery team at Ångströms Laboratory is one of the global leaders in its field. So I think this sound fascinating and I’m eager to see what it leads to,” says Fride Vullum-Bruer at the Norwegian University of Science and Technology (NTNU), who is also engaged in developing new battery concepts.

An Achilles’ heel

Problems with battery technologies still comprise an Achilles’ heel for certain uses of alternative energy. We use batteries in innumerable electronic products and they have become smaller and lighter, but essentially nothing revolutionary has happened with batteries since they were first devised 215 years ago.

Today’s Li-ion batteries are rechargeable and pack a great punch but they have their negative sides. Contemporary battery technology is expensive and is still keeping most motorists from switching from exhaust-spuming internal combustion engine cars to clean-running EVs.

Mineable lithium supplies are limited and huge amounts of the element are needed. There is simply not enough available to replace all the petrol and diesel vehicles of the world with ones running on lithium-ion batteries. These batteries also can contain toxic materials which make them expensive to recycle.

The search is on for alternatives

So research teams the world over are striving to find smarter and more environmentally friendly battery concepts. NTNU scientists have also been working on greener batteries to make lithium perform as a more efficient cathode after being combined with other materials in a compound.

But the method for retrieving and recycling lithium used by the scientists at Uppsala University is advanced and innovative.

They found a good way to extract lithium from depleted batteries so it can be re-used through low-energy techniques to make new batteries. This can be done using renewable biological material, in this case from alfalfa seeds and pine trees. The recycling of the new batteries, once they too age and become inefficient, can also be implemented with low energy costs using the environmentally friendly liquids water and ethanol.

A 99 percent recovery

Such recycled Li-ion batteries can deliver 99 percent of the energy that the previous battery provided. With future modifications the researchers think they can raise that performance figure even higher.

“The use of organic materials from renewable sources makes it possible to solve several of the problems that would arise from a huge rise in the use of lithium batteries,” says Daniel Brandell, one of the scientists behind the breakthrough at Uppsala.

“But above all, it’s a major step forward that, to a high degree and in a simple, environment-friendly way, the lithium from these batteries can be recovered. These solutions are also potentially very cost-effective,” says Brandell.

------------

Read the Norwegian version of this article at forskning.no

Translated by: Glenn Ostling